- View Mobile Number

sales@bsjagdev.com

3.75 Lac / Piece

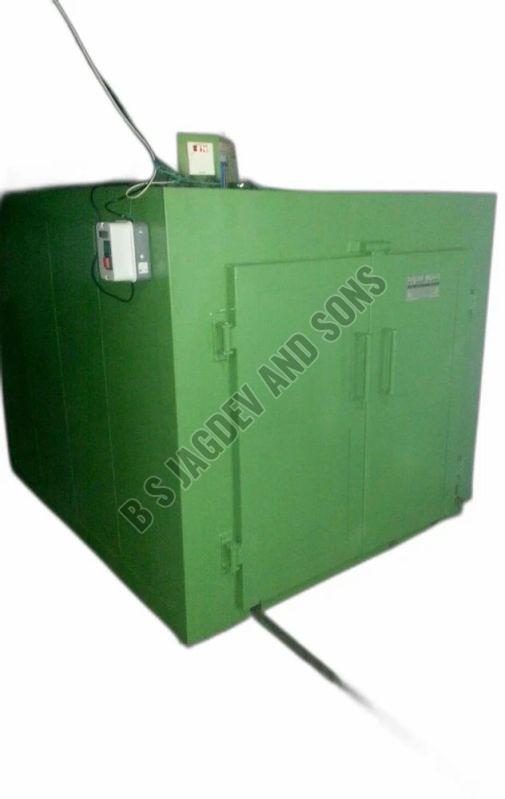

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 440 V |

| Country of Origin | India |

| Application | Industrial Use |

| Click to view more | |

Product Details

Automatic Grade

Automatic

Driven Type

Electricity

Material

Mild Steel

Brand Name

BSJS

Air-Flow Direction

Cross-Flow Type

Frequency

50 Hz

Door Type

Double Door

Temperature

100-200 Deg. Celsius

Batch ovens allow for curing or drying in single or smaller batches. They often use wheeled racks, carts or trays (depending on the size of the oven) to bring the part(s) being processed into the oven. These ovens are best for parts that are too difficult to run on a conveyor and for items with different sizes, shapes and thermal requirements. To run items on a lower temperature, the chamber must first be cooled and then reheated.

The oven is designed to operate at 500°Cmaximum temperature and includes the following special features:

- 8" inch thick insulated walls, ceiling and floor with cart tracks (if required)

- 1" Circulation fan

- CRS exterior painted machine gray

- Stainless Interior

- UL listed Control Panel

- Electronic temperature controller and high limit

- 800,000 BTU burner

- 800 CFM Exhaust Blower

Looking for "High Temperature Electrical Oven" ?

Piece